Thermal-Fluid Sciences I - ProTec Anti-friction Metal Treatment

Students - Beau Fant, Shiva Hemmatian, and Chris Lanham

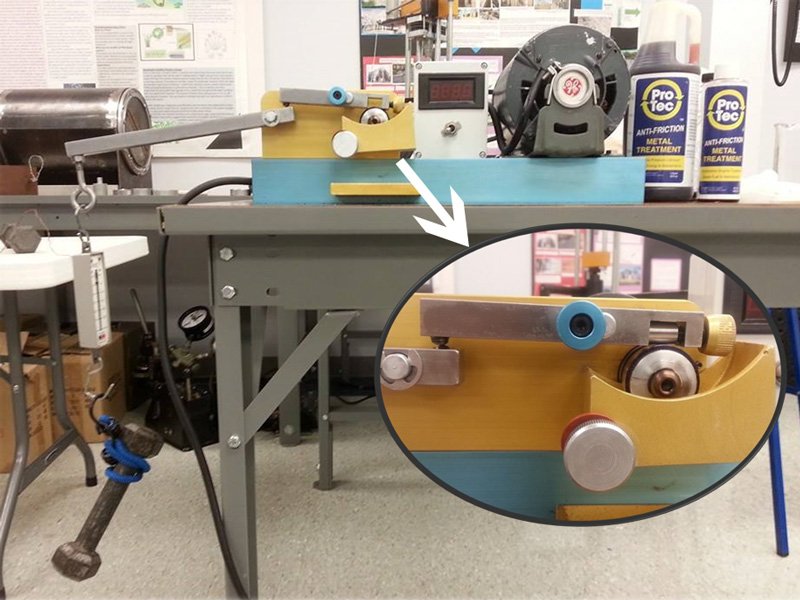

ProTec (http://www.proteclubricants.com/AFMT/Home.html) is a Christian-led company out of Memphis that produces an anti-friction metal treatment for industrial, automotive, agricultural, and aviation applications. The goal of ProTec is to reduce the wear and tear in metal components by treating the metal surfaces. Our experiment attempts to determine how much longer ProTec treated bearings will last compared to untreated bearings in the event of oil starvation. To simulate this, the metal was pretreated with ProTec using resistance weights applied to the lever arm seen in the picture. The bearing and wheel were then wiped clean, three drops of oil were added to simulate residual oil left from oil starvation, and the apparatus was then run to failure under a weight of 3 pounds, which represents the “stall” weight for bare metal found from previous experiments.

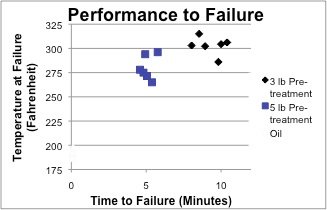

By running the pretreated metal under a weight of 3 pounds, we recovered the approximate amount of time it takes for ProTec to wear off. When all of the ProTec treatment wore off, the mechanism would stall, leaving bare metal on metal contact. The same experiment was run without pretreating the bearings. The results can be seen in the graph below. In terms of time to failure, ProTec clearly outlasts plain oil. We also observed that lower pretreatment loads resulted in longer run-times, possibly due to less wear on the bearing during the pre-treatment time, resulting in a smaller surface area. A PDF version of a poster we presented at the Union University Scholarship Symposium can be found here.