Our Students

The Department of Engineering encourages its students to be engaged within the department and beyond, to the broader campus, the community, and other countries. Engineering students are active in Campus and Community Day, with projects ranging from building an improved bridge for a community bike trail to building an on-campus swing that is enjoyed by students and visitors to campus. The department has been involved with engineering-specific mission trips for years; in recent years, students and professors have worked together to install alternative energy solutions at an orphanage in Honduras.

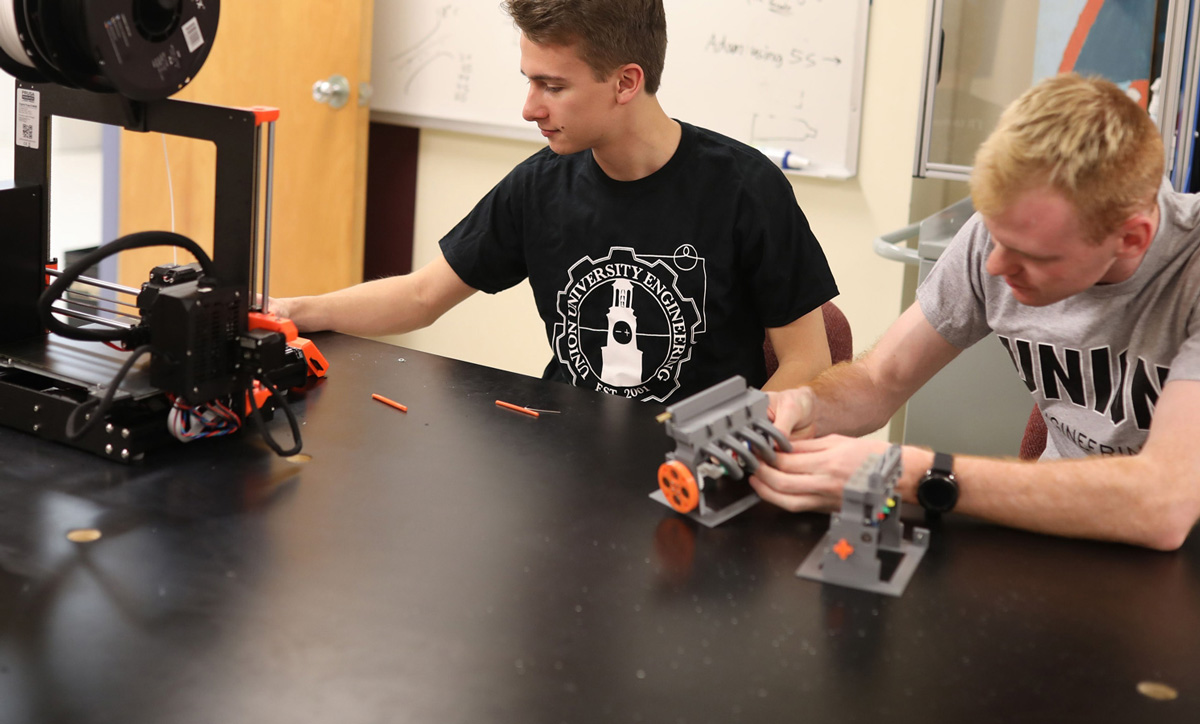

In addition to cultural engagement, students in the engineering department do some tremendous academic work, with course projects starting in the freshman year and culminating in the senior design project. Past projects have included building a robot to clean drains in the manufacturing area of a local company, designing a machine to roast coffee, and testing the aerodynamic principles of bicycle helmets.

Service through Engineering Award

The Department of Engineering awarded the 2021 Service through Engineering award to Luis Larrinaga for his tremendous contributions to the face shield project. The department used its 3D printers to provide over 10,000 face shields to health care providers and others throughout the region, and Luis was an early volunteer and a faithful participant for the duration of the project.

Academic Excellence Medal in Engineering

The Department of Engineering awarded the 2021 Academic Excellence Medal to John Mayer, the first student who completed both the electrical and mechanical concentrations — and he did so with academic excellence!

Undergraduate Research - Spring 2025

Design of Expansion Arbor for Three-Phase Coils (O)

Presenters: Jonathan Brewer, Daniel Lancaster, and Nathaniel Thomas

Faculty Project Advisors: Jay Bernheisel and Georg Pingen

In this project, our design team was tasked with standardizing the process by which ERMCO winds three-phase coils on their mechanical arbor. As these require various plate dimensions, our team created an expansion shaft in order to fit all of the dimensions with a single modular device, which will implement a significant improvement for ERMCO's arbor system at their Dyersburg plant. This was accomplished by creating a mechanism that will allow for easy adjustment of the dimensions, allowing the coil to be wound in the appropriate sizes. Standardizing the process will yield substantial improvement in changeover time for the operator, leading to less overall downtime for the plant. This presentation will detail the entire engineering process, from the original prompt to design conceptions and the final product.

Large Spool Lifting (O)

Presenters: Colby Davis, Ryan Keeton, and Mikaila Rogers

Faculty Project Advisors: Jay Bernheisel and Georg Pingen

This project entails the design for building a device capable of lifting and moving large spools up to 6,000 pounds. The project was given by Prysmian to Colby Davis, Mikaila Rogers, and Ryan Keeton. Prysmian manufactures fiber optic cables and uses large metal or wooden spools to handle the cables in their facility and to ship to consumers. At the conception of this project, they had no good way to handle these large spools. The creation of this spool lifting device will enable them to better handle and move these large spools that can otherwise be very difficult to maneuver

Design and Construction of Small-Scale Wind Tunnel (O)

Presenters: Ian Banderchuk, Jewelia Black, Ethan Brasher, and Michael Kirk

Faculty Project Advisors: Jay Bernheisel and Georg Pingen

Wind tunnels are used as a tool to model air flow around objects. This can be useful in the design and testing of airplane, car, and spacecraft components to list a few. This project includes the design and construction of a small-scale wind tunnel. Our team, in collaboration with Young Touchstone in Jackson, TN, worked to design, fabricate, and assemble a cost-effective wind tunnel solution. We worked to specify pressure drop through the wind tunnel as well as desired air velocity for testing. Subsequently, we moved to ranking and choosing key components for the wind tunnel, like the fan and variable frequency drive. We also designed the key structural components. Finally, we selected appropriate sensors, flow visualization equipment, and other hardware before finally assembling the completed wind tunnel.

Hitachi Energy High Temperature Mold Vacuum Seal Project (O)

Presenters: Jacob Carbonell, Eli Snelson, and Micah Valdivia

Faculty Project Advisor: Georg Pingen

Our team worked on a project with Hitachi Energy in Alamo, Tennessee, a major supplier of parts in the energy industry. We were tasked with addressing the occasional trouble they were having with bushing, which is an integral part of transformers. They were having a problem where air was leaking into the bushing during the casting process allowing for porosity to form in the exterior of the bushing which could compromise the functioning of the bushing. Thus, the Hitachi Energy High Temperature Mold Vacuum Sealing Project aimed to design and produce a solution to Hitachi's problem of occasional porosity in bushings. To solve this problem, we designed an additional vacuum seal under the problematic seal to create a vacuum around the problematic area thus eliminating porosity.

DCI Conveyor Belt Slippage Solution Project (O)

Presenters: Jacob Arehart, Caleb Krueger, and Braeden McAlister

Faculty Project Advisor: Georg Pingen

This project sought to find a solution to the common problem of conveyor belt slippage. Diversified Conveyors, a company dedicated to providing innovative conveyor belt solutions to a variety of customers, requested that we design, prototype, and test an early warning system that will detect when their conveyor belts start to slip off the rollers. Their goal was to drastically reduce damage, downtime, and maintenance that is caused by the belts slipping. They hoped that our lack of experience in the conveyor belt industry would help us find a more creative solution than what is already offered on the market. We followed the engineering design process to identify the important variables, generate prototypes, evaluate these prototypes, build a prototype, and then finally test our prototype at DCI's state-of-the- art conveyor belt training facility. From our testing, we concluded that our preferred prototype could fulfill our requirements. We recommend that DCI bring our final design to market and install it throughout their current and future conveyor belt systems.

Testing Factors Affecting Goalkeeper Performance (P)

Presenter: Kyle Whitmark

Faculty Project Advisor: Don Van

One of the most important jobs on the soccer field is that of the goalkeeper. The goal of this experiment is to test different factors affecting the performance of the goalie. Eight factors that will be tested are: shoes, gloves, skill level, distance, kicking foot, kick type, ball inflation, and time of day. To design and analyze this experiment more effectively, the fractional factorial method was used to reduce the 256 (28) original experiments needed to a more manageable 16 (28-4) experiments.

Rubber Band Flight Factorial Experiment (P)

Presenter: Judy Lampley

Faculty Project Advisor: Don Van

The aim of this experiment will be to determine which factors affect the distance of the flight of a rubber band. The factors that will be considered are as follows; the length of rubber band, thickness of rubber band, the length stretched, whether or not it has a staple in the middle, whether it is twisted or not, and whether or not they have been stretched prior to the experiment. With this many different factors changing between each test, there are 144 different experiments to do. This can be reduced through the factorial experiment method. To launch these rubber bands consistently, the use of a launcher device with a variable stretching ability will be needed. A device to pre-stretch rubber bands consistently will also be needed. The different diameters of the rubber bands are going to be 7-inch and 3-inch, and the thicknesses will be 1/16-inch, 1/8-inch, and 1/4-inch. The length stretched will be based on percent of total length of a given rubber band due to the fact that a 3-inch diameter rubber band can stretch to 6-inch, but a 7-inch rubber band cannot. The percent stretched will be 100%, 125%, and 150%. A 100% stretch would be stretching a 3-inch rubber band to 6 inches. The distance flown will be measured via a tape measure and will be measured from a predetermined spot on the launcher to the closest edge of the rubber band. By the end of this experiment, the factors that affect the distance the most will be listed on a Pareto diagram.

Electrical Circuit Integrator Using Filters (P)

Presenters: Josiah Hays, Matthew Meyn, Bobby Perry, and Timothy White

Faculty Project Advisor: Jeannette Russ

Our group used a sine-wave generator, coupled with filters, to make a electrical integrator. Sine-wave generators have many applications including in-power inverters and in- testing audio and communications systems. We will design a sine-wave generator circuit by taking a square-wave generator and connecting it to a sequence of low-pass filters. The filters remove the harmonics of the square wave, producing a clean sine wave of the desired frequency as a result.

Maximizing RC Car Jump Distance (P)

Presenter: Jewelia Black

Faculty Project Advisor: Don Van

This study explores the factors influencing the distance traveled by an RC car after a jump, with the goal of maximizing performance. Key variables include speed, terrain type, ramp angle, car type, added weight, initial distance from the ramp, signal strength, and battery level. Each factor was tested at two levels, such as fast vs. slow speed, smooth vs. rough terrain, and major vs. minor jump angles. A fractional factorial design was used to reduce the number of experimental trials from 256 (or 28) to 16 (or 28-4) while still capturing significant interactions. The results will help identify optimal conditions for achieving maximum jump distance, offering valuable insights for RC car enthusiasts and hobbyists.

Determining the Most Influential Factors on the Accuracy of Disc Golf Putting (P)

Presenter: Benjamin Kuhl

Faculty Project Advisor: Don Van

Disc golf is a popular activity for many people, and putting is a large part of the game. For this experiment, the goal was to study the different factors that can affect the accuracy of putting. A basket was set up within a controlled environment and tests were run. The following eight factors are considered relevant to this study: weight of the disc, distance from basket, wind speed, the individual putting, the day on which the putting was done. obstruction, elevation, and whether the individual follows a consistent routine before putting. The 16th fractional factorial design of experiment method was then used to conduct this experiment with 16 instead of the full 256 experiments. Throughout the experiment, the data was imported to Excel and then later analyzed.

Minimizing Your Heart Rate During a One-Mile Run (P)

Presenter: Landon Haywood

Faculty Project Advisor: Don Van

Our heart rate determines how well-conditioned we are when we run a mile. A lower heart rate correlates to our bodies being in better shape. This experiment aims to determine which factor influences our heart rate the most during a one-mile run using the 16th Factorial Design method. The eight factors in this experiment are: consuming 100 or 200 mg of caffeine before the run, running in the morning or at night, running a flat or hilly route, consuming the caffeine right before or thirty minutes before the run, eating or not eating before the run, static stretching or dynamic stretching, no music or music, and running shoes or everyday shoes. The heart rate will be analyzed and tracked using an Apple watch periodically throughout the run while running a consistent eight-minute mile pace.

Hummingbird Detection with Bandpass Filters (P)

Presenters: Cameron Kennedy, Gideon Miller, Samuel Moss, and Jake Pingen

Faculty Project Advisor: Jeannette Russ

A hummingbird feeder is a common signature and decoration for households across North and South America, providing both an aesthetic appeal of the feeder itself as well as entertainment. However, it can be somewhat cumbersome to constantly monitor the hummingbird feeder for the activity of hummingbirds. To help address this issue, our team plans to use a bandpass filter, which is a device capable of isolating certain electrical frequencies and is composed of operational amplifiers, resistors, and capacitors. Our team plans to design a filter of this type to isolate the hummingbird's natural chirps and/or wing beat frequencies, which could then be used to signal when a hummingbird is at the feeder.

Bandpass Filter-Based Guitar Tuner (P)

Presenters: Jonathan Carroll, Jordan Prunty, and Cody Tjomsland

Faculty Project Advisor: Jeannette Russ

Bandpass filters (BPFs) allow only a specific range of frequencies to pass through, making them useful for many real-world tasks. This project explores the design of BPF to tune a guitar by isolating specific frequencies. Using TL081 operational amplifiers, resistors, and capacitors on a protoboard, the circuit processes a sinusoidal input from a function generator, targeting the note C (~261.63 Hz). Rather than real-world signals, we use the function generator to provide a clean input, keeping the focus on the BPFs. The system features three filters: one activates an LED when the correct frequency is detected, while two additional filters indicate if the pitch is too high or too low. By using a function generator in place of analog-to-digital conversion circuitry, the design emphasizes the BPFs' precision and functionality. This work demonstrates frequency selectivity in action, blending circuit design with a practical musical application

Analysis of Conditions Influencing the Accuracy of a 3-Point Shot Utilizing Fractional Factorial Experimental Design (P)

Presenter: Zane Bolton

Faculty Project Advisor: Don Van

There are a variety of external factors that affect the accuracy of a 3-point shot in basketball. The most skilled athletes can adapt and perform at a high level of consistency in games despite these factors, having prepared for a variety of situations in their training. This experiment studies how each of 8 different 2-level factors affects the accuracy of a 3-point shot from the men's college line at the top of the key. The factors are shooting stationary vs. moving, guarded vs. unguarded, rushed vs. taking your time, warmup vs. no warmup, audience present vs. none, off the catch vs. off the dribble, tired and winded vs. rested, and under pressure vs. not under added pressure to make the shot. This experiment makes use of the 16th fractional factorial design to conduct 3 trials of 10 shots under each of 16 unique 18Twenty-Second Annual Union University Scholarship Symposium sets of conditions. The data collected are the percentages of shots made (out of 10) in each set of conditions, which are then averaged across the 3 trials. The data is analyzed using Excel to ultimately determine which factor has the greatest effect on the accuracy of shooting a 3 pointer.

Experiments to Enhance Mechanics of Materials (P)

Presenters: Landon Haywood, Judah Lampley, Ryan Metcalf, and Elijah Patton

Faculty Project Advisor: Georg Pingen

Many of the concepts in Mechanics of Materials can be difficult for students to understand based on in-classroom lecture alone. Having a hands-on lab can enhance students' ability to understand and apply the concepts learned in lecture; however, the equipment used in these types of labs is often prohibitively expensive. However, with increasing access to low-cost electronics, 3d printers, and other makers items, the ability to design and make customized lab equipment has become increasingly viable. We took on the goal of creating two pieces of lab equipment for use in Mechanics of Materials. The first project is a low-cost tensile tester for 3d printed samples. Typical tensile testers cost anywhere from $10k to $20k. A low-cost tester would allow for a better understanding of how printing methods, filaments, and formats would affect tensile strength. The second project is an experimental apparatus for observing the forces in statically indeterminate structures. The completion of these projects will help students in Mechanics of Materials to more fully understand the concepts learned in lecture.

Factors Affecting Flight of a Pump Bottle Rocket (P)

Presenter: Eli Patton

Faculty Project Advisor: Don Van

As exploration into space furthers, rockets are being tested and pushed to their limits to maximize speed, distance, and efficiency. Companies like NASA and SpaceX's primary mission is to learn more about space and offer spacefaring for more professional, government, and civilian uses. However, in this experiment, rockets will not be exploring the bounds of outer space travel, but they will be tested to find maximized thrust and distance based on different variables. Different compressed air bottle rockets will be experimented with. An air pump will pressurize the air in the rocket, ejecting a liquid propellant, shooting the rocket. The factors tested in this study are: rocket size, type of liquid propellant, amount of liquid propellant, lift-off angle, use of fins, and use of a nose. An eighth fractional factorial design of the experiment will be conducted to reduce the total number of experiments from 64 to a more manageable 8.

Transforming Music Into Light (P)

Presenters: Rachel Allabaugh, Mia Duncan, and Stacia Talbott

Faculty Project Advisor: Jeannette Russ

Filters can be used in circuits to control the effects of a variable input, either limiting the results to high or low inputs, or a bracketed middle range of inputs. Understanding music only through listening to an audio file can be limiting, but filters can be used to convert an audio file from pitches to LED flashes which will allow users to see the changes in pitch throughout a song. Using a variable function generator with changing voltages that correspond to notes in a song, we built a circuit using filters for each pitch, so that the corresponding LED would light up while the pitch was playing.

Optimizing Bending Strength of 3d Printed Beams (P)

Presenter: Ryan Metcalf

Faculty Project Advisor: Don Van

With the boom in low-cost 3d printers, 3d printed parts are becoming increasingly common in academic, professional, and personal settings. However, many FEA software packages such as Fusion 360 are unable to perform static stress analysis of 3d printed parts due to their unique strength characteristics. Furthermore, the specific print settings used will change the strength of the beams. In order to better understand the material properties of 3d printed parts, I will analyze several factors the bending strength of 3d printed beams to optimize their strength. These factors will namely be print orientation, infill percentage, wall thickness, print speed, and beam design. The weight supported as well as the position and type of break will be observed. The design of this experiment will use the fourth fractional factorial method to determine which factors have the greatest effect on bending strength.